|

INCERAMICS Sp. z o.o. - PRODUCTS

Specialized components, manufactured in INCERAMICS Sp. z o.o. for special orders, are not shown in our current offer.

We produce ceramic parts according to Client's brief fordesign. We offer also technical advices in ceramic technology, properties of materials,

designing and application of ceramic components.

Our products are typically available in material versions:

A96 - material Al2O3 96% - working temperature up to 1500°C

A99 - material Al2O3 99% - working temperature up to 1750°C

Z1 - material ZrO2 92% - working temperature up to 2200°C

For our Client's demand:

we offer another ceramic materials

we produce components in non-standard dimensions

we cover components with a glaze

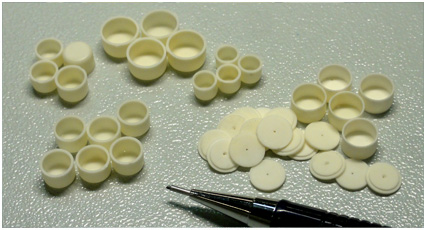

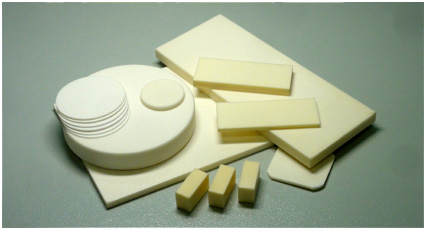

LABORATORY EQUIPMENT

|

Permanently available in various shapes and dimensions

Working temperature up to 1750°C and to 2200°C

We offer also in non-standard dimensions.

|

Material A96

Material A99

Material Z1

Examples |

|

Permanently available in various shapes and dimensions

Working temperature up to 1750°C and to 2200°C

We offer also in non-standard dimensions.

Outer diameter from D=10 to D=100 mm.

Height from H=5 to H=200 mm.

|

Material A96

Material A99

Material Z1

Examples |

|

Permanently available in various shapes and dimensions

Working temperature up to 1750°C and to 2200°C

We offer also in non-standard dimensions.

|

Material A96

Material A99

Material Z1

Examples |

|

Permanently available in various shapes and dimensions

Working temperature up to 1750°C and to 2200°C

We offer also in non-standard dimensions.

|

Material A99

Material Z1

Examples |

|

Permanently available in various shapes and dimensions

Working temperature up to 1750°C and to 2200°C

|

Material A99

Material Z1

Examples |

|

Permanently available in various shapes and dimensions

Working temperature up to 1750°C and to 2200°C

With pestle in a set

We offer also in non-standard dimensions.

|

Material A99

Material Z1

Examples |

|

Permanently available in various shapes and dimensions

Working temperature up to 1750°C and to 2200°C

We offer also in non-standard dimensions.

|

Material A96

Material A99

Material Z1

Examples |

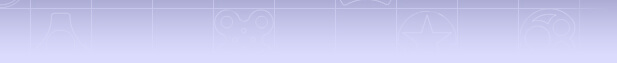

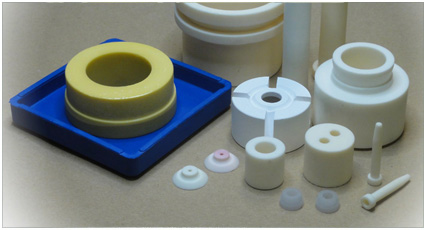

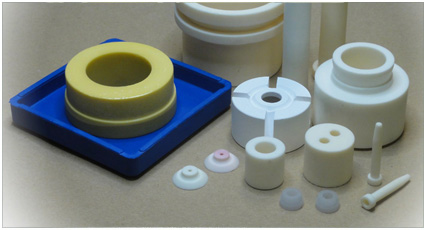

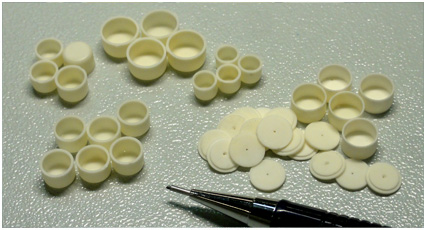

CIM - CERAMIC INJECTION MOLDING

Ceramic Injection Molding is a technology that enables

large-scale production of ceramic elements with complex shapes and narrow dimensional tolerances without the use of machining

finishing. Adapted injection molding machines of the same type as for thermoplastic injection are used for ceramic injection.

The design of injection molds and the principles of designing products for production in this technology also remain the same,

as for plastics.

This technology is not profitable with short production runs.

High pressure ceramic injection is the basic technology used in our company. We offer production of parts up to 100 x 100 mm.

|